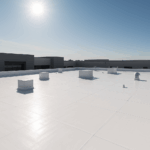

Improper installation of roofing felt can lead to various issues and roof problems later on. Here are three common mistakes that can cause problems:

- Incorrect Overlapping: One of the primary functions of roofing felt is to provide a secondary layer of protection against water infiltration. Proper overlapping is crucial to ensure water resistance. One common mistake is inadequate overlapping of the felt sheets. If the overlap is insufficient, it can create vulnerable areas where water can penetrate. The recommended overlap for roofing felt is typically about 2 to 4 inches horizontally and vertically.

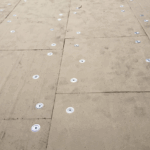

- Improper Attachment: Roofing felt should be securely attached to the roof decking to prevent it from shifting or tearing during installation or due to weather conditions. Inadequate attachment, such as using too few fasteners or failing to properly secure the edges, can result in loose or wrinkled felt. Loose felt can be prone to tearing, shifting, or even blowing off during strong winds, compromising the roof’s integrity and water resistance.

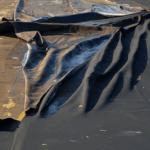

- Wrinkles and Bubbles: Wrinkles and bubbles can occur when roofing felt is not properly installed or when excessive moisture becomes trapped beneath the felt during installation. These imperfections can create areas where water can collect and potentially seep into the roof structure. Over time, the trapped moisture can lead to rot, mold growth, or other forms of water damage.

To avoid these problems, it is essential to follow manufacturer guidelines and best practices for roofing felt installation. Additionally, it is recommended to have a professional roofer like Litespeed Construction install or oversee the installation of the roofing felt to ensure it is done correctly and minimize the risk of future roof problems.

If you already have a roof leak that you suspect is due to improper installation, we can help. The first step is getting us to come out and look at your roof. Request a free detailed estimate below.