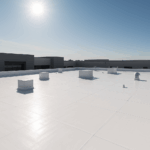

Commercial roofing systems are built for durability—but even the toughest materials fail without proper maintenance and timely inspections. The membrane of a commercial roof acts as the first line of defense against rain, UV rays, wind, and fluctuating temperatures. When that membrane begins to fail, it doesn’t just affect the roof—it endangers the entire building, its occupants, and its contents.

For Knoxville-based business owners and facility managers, understanding the signs of commercial roof membrane failure is vital. Tennessee’s humid climate, frequent rainstorms, and seasonal temperature swings make flat and low-slope roofs especially vulnerable. Litespeed Construction, a local leader in commercial roofing, has helped dozens of local businesses avoid major structural damage by catching these signs early.

Key Takeaways

💡Blistering, ponding water, and cracks are red flags for membrane failure.

💡Membrane issues often start small but lead to major repairs if ignored.

💡Proper inspection and timely maintenance can prevent up to 80% of premature roof failures.

💡Knoxville’s climate increases the likelihood of moisture-related roof issues.

What Is a Commercial Roof Membrane?

A commercial roof membrane is a protective layer that sits atop flat or low-slope roofs. It is designed to provide waterproofing and resist weathering. Common types include:

| Membrane Type | Material | Lifespan (Years) | Common Failures |

|---|---|---|---|

| TPO | Thermoplastic Polyolefin | 15–20 | UV degradation, seam failure |

| EPDM | Ethylene Propylene Diene Monomer | 20–25 | Shrinkage, cracking |

| PVC | Polyvinyl Chloride | 20–30 | Punctures, chemical damage |

| Modified Bitumen | Asphalt-Based | 10–20 | Blistering, granule loss |

Early Warning Signs of Commercial Roof Membrane Failure

1. Blistering and Bubbling

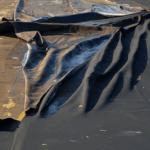

Blisters occur when air or moisture becomes trapped under the membrane. This can happen due to poor installation, thermal expansion, or water infiltration.

Fact: According to the NRCA, improper roof ventilation is responsible for over 25% of all blistering issues in commercial membranes.

2. Ponding Water

Ponding water (standing water that remains more than 48 hours after a storm) is a major warning sign. It causes additional stress on the membrane and can lead to leaks, mold, and membrane degradation.

Stat: The U.S. General Services Administration recommends all commercial roofs be sloped to drain within 48 hours to prevent premature deterioration.

3. Cracks, Tears, or Splits

Over time, roofing membranes can crack due to thermal expansion and contraction cycles, particularly in Tennessee’s variable climate. EPDM and PVC roofs are most susceptible.

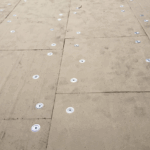

4. Loose or Open Seams

Membranes are often welded or adhered at seams. If these seams begin to separate, water can easily seep underneath, leading to insulation damage and leaks.

5. Membrane Shrinkage

EPDM membranes are especially vulnerable to shrinkage, which can pull the membrane away from walls or penetrations, leaving areas exposed.

6. Discoloration or Staining

A visible change in color often signals UV damage, chemical exposure, or mold growth under the surface—common with TPO and PVC membranes.

Long-Term Effects of Ignoring Roof Membrane Failure

Delaying membrane repairs leads to exponentially higher costs and can jeopardize the safety of your building. Here’s a breakdown:

| Issue Ignored | Cost of Delay | Potential Outcome |

|---|---|---|

| Minor seam separation | $500 now vs. $5,000 later | Full membrane replacement required |

| Ponding water | $0 now vs. $10,000+ later | Structural deck rot, insulation ruin |

| Blistering | $1,000 now vs. $8,000+ later | Total loss of waterproofing |

| Cracking | $800 now vs. $15,000+ later | Severe interior water damage |

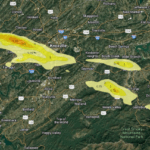

Why Knoxville Is at Greater Risk

Knoxville’s climate presents unique challenges for commercial roofs:

- High Humidity accelerates mold growth and moisture retention.

- Frequent Storms stress membranes, especially during spring and summer.

- Freeze-Thaw Cycles in winter cause expansion and contraction, which stresses seams and fasteners.

- UV Radiation during long summer days breaks down membrane surfaces.

According to NOAA Climate Data, Knoxville receives over 50 inches of rain annually, making waterproofing critical.

How Litespeed Construction Helps Prevent Roof Membrane Failure

Litespeed Construction is Knoxville’s go-to roofing company for comprehensive commercial roof care. Here’s what sets them apart:

- Thermal Imaging Inspections to detect hidden moisture

- Seam Welding Expertise for EPDM, TPO, and PVC systems

- Customized Maintenance Plans tailored to your building and budget

- Free Consultations with commercial property owners and managers

With decades of experience in Tennessee’s roofing industry, Litespeed Construction understands how to spot early signs of failure and take proactive measures.

Pros and Cons of Commercial Roof Membranes

| Pros | Cons |

|---|---|

| Cost-effective compared to pitched roof systems | Susceptible to pooling if improperly installed |

| Easy to install and repair | Shorter lifespan in extreme climates |

| Energy-efficient (especially TPO and PVC systems) | Vulnerable to punctures from debris or foot traffic |

| Compatible with solar panels and HVAC systems | Requires regular inspections to remain effective |

Web Ratings and Industry Trust

Litespeed Construction has completed over 500+ commercial roofing projects in East Tennessee.

| Review Site | Litespeed Construction Rating |

|---|---|

| Google Reviews | 4.9 / 5.0 |

| Angi (formerly Angie’s List) | 4.8 / 5.0 |

| Yelp | 5.0 / 5.0 |

FAQs About Commercial Roof Membrane Failure

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Look for bubbles, cracks, loose seams, and ponding water after rain.

Twice per year—preferably in spring and fall—and after major storms.

Yes, early-stage issues like minor blisters or seam separations are usually repairable.

15–30 years, depending on the material and environmental conditions.

Through infrared thermal imaging and core sample testing.

Yes, often under Section 179 of the IRS tax code. Consult your CPA.

TPO or PVC membranes perform well due to their energy efficiency and moisture resistance.

Yes, they assist with inspections, documentation, and adjuster coordination.

Visit Litespeed Construction’s contact form or call (865) 297-3286.