Working on commercial rooftops is inherently dangerous. According to OSHA, falls from heights remain the leading cause of construction-related fatalities in the U.S., with roofing being one of the highest-risk occupations. Understanding what safety equipment is needed for commercial roofing is not just about checking compliance boxes—it’s about protecting lives, ensuring jobsite productivity, and minimizing liability.

Whether you’re a building owner, property manager, or roofing contractor in East Tennessee, safety is a non-negotiable part of the commercial roofing process. Let’s break down exactly what gear, systems, and protocols are required to maintain OSHA compliance and keep your roofing crew safe on the job.

Key Takeaways

💡OSHA requires fall protection for any work done at heights of 6 feet or more.

💡Personal protective equipment (PPE) is mandatory for every commercial roofing technician.

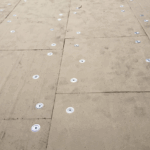

💡Roofers must use certified anchor points, guardrails, and harness systems to prevent falls.

💡Local roofing professionals like Litespeed Construction follow strict safety protocols that exceed federal standards.

Why Roofing Safety Matters in East Tennessee

East Tennessee, including Knoxville and surrounding areas, presents unique challenges for commercial roofing safety. From rapidly changing weather conditions to steep-sloped industrial buildings, the risks are significantly heightened. High winds, summer heat, and slippery surfaces during the rainy season all increase the potential for falls and injuries.

In this region, ensuring the right safety equipment is needed for commercial roofing not only protects the workers on-site, but also protects the property owner or general contractor from potential legal consequences, insurance complications, and expensive project delays.

Required Safety Equipment for Commercial Roofing

Understanding what gear is needed for commercial roofing involves categorizing the various types of safety equipment required to meet OSHA guidelines and ensure worker safety. Below is a detailed breakdown:

🧰 Safety Equipment Categories and Examples

| Safety Gear Category | Equipment Examples |

|---|---|

| Fall Protection Systems | Guardrails, Personal Fall Arrest Systems (PFAS), Safety nets |

| Personal Protective Gear (PPE) | Hard hats, gloves, safety boots, safety glasses, goggles |

| Anchorage Systems | Roof anchors, tie-backs, vertical lifelines, horizontal lifelines |

| Ladders & Roof Access | OSHA-rated extension ladders, roof hatch ladders, scaffolding |

| Weather Protection Gear | Non-slip waterproof boots, heat-reflective vests, rain-resistant outerwear |

Each category plays a vital role in mitigating specific hazards—whether it’s preventing falls, protecting against head trauma, or ensuring safe access to elevated surfaces.

OSHA Commercial Roofing Safety Standards

OSHA (Occupational Safety and Health Administration) mandates specific safety protocols for roofing contractors. These regulations exist to standardize the use of fall protection and other essential gear across commercial job sites.

| OSHA Regulation | Description |

|---|---|

| 1926.501(b)(1) | Fall protection required at heights of 6 feet or higher |

| 1926.503 | Mandatory fall protection training for all roof workers |

| 1926.104 | Lifeline systems must support at least 5,000 lbs |

| 1910 Subpart D | Walking-working surfaces must be stable and slip-resistant |

Source: OSHA.gov

Meeting these standards is not optional. Failing to comply can result in severe fines and, more critically, increased chances of workplace injury or death.

Common Roofing Hazards & Prevention Tactics

Commercial roofing sites are filled with hazards, and knowing how to prevent them is essential.

| Hazard | Prevention Solution |

|---|---|

| Falls from height | Guardrails, PFAS, anchor systems |

| Electrical shock | Avoiding power lines, using insulated tools |

| Slips and trips | Non-slip footwear, clear walkways, safety mats |

| Sun and heatstroke | Regular hydration, shaded break areas, sun hats |

| Ladder collapses | Use OSHA-rated ladders secured properly with standoffs |

Roofing contractors must conduct daily hazard assessments and ensure that every piece of safety equipment needed for commercial roofing is available and functioning properly.

Roofing Safety Equipment Checklist (Used by Litespeed Construction)

Litespeed Construction, a trusted name in East Tennessee commercial roofing, ensures every technician is equipped with the full suite of safety gear. Their daily protocols include a full safety inspection before work begins.

Essential Equipment Used:

✔ Fall arrest harness (certified and OSHA-compliant)

✔ 6 ft. lanyard with energy shock absorber

✔ Anchored vertical and horizontal lifeline systems

✔ OSHA-rated ladders with non-slip feet and standoffs

✔ High-visibility safety vest

✔ Anti-slip, steel-toe roofing boots

✔ ANSI-certified hard hat

✔ On-site first aid kit

✔ Safety training logs and documentation

FAQs About Commercial Roofing Safety Gear

Yes. OSHA mandates fall protection for anyone working at heights of 6 feet or more.

They’re attached to certified roof anchors rated to support at least 5,000 lbs.

Puncture-resistant, non-slip boots with steel toes offer the best protection.

Yes, though OSHA provides national minimums. States like Tennessee follow OSHA with added guidelines from TNOSHA.

Yes, but only with anti-slip gear, traction mats, and additional fall protection.

Annual fall protection and ladder safety training is required under OSHA 1926.503.

They are not always mandatory but are strongly recommended alongside PFAS systems.

Yes. OSHA citations can exceed $14,000 per violation.

In some cases, especially when unsafe conditions were known and not addressed.

Through daily safety briefings, full gear checks, certified equipment, and OSHA-compliant procedures.

Protect Your Building and Workers—Book a Roof Inspection Today

In commercial roofing, safety is not optional—it’s essential. Every single item on your jobsite, from a basic harness to a secure ladder system, plays a role in preventing injuries and fatalities. With strict OSHA regulations and high risks, knowing what safety equipment is needed for commercial roofing is the foundation of a responsible, reliable, and regulation-compliant project.

Litespeed Construction takes commercial roofing safety seriously. Our teams are trained, certified, and fully equipped to deliver high-quality results while protecting workers and clients alike. Whether you’re managing a retail property, warehouse, or multi-unit commercial facility, our safety-first approach ensures your project stays compliant and on schedule.

👉 Don’t wait for an accident to highlight what was missing—schedule a commercial roof inspection with Litespeed Construction today. We’ll evaluate your roof, assess safety risks, and provide a full report to help protect your investment and the people who work on it.