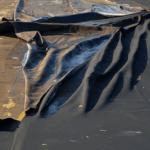

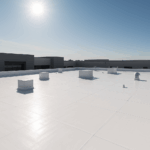

If you’ve ever driven past a large commercial building and noticed a clean, flat black roof surface, there’s a good chance it was EPDM roofing. This synthetic rubber roofing membrane has been a leading choice in commercial and industrial roofing systems across the U.S. since the 1960s.

EPDM roofing, or Ethylene Propylene Diene Monomer roofing, is best known for its durability, weather resistance, and cost-effectiveness. Whether you’re dealing with harsh Northeast winters, the sweltering heat of the South, or the unpredictable weather patterns in the Midwest, EPDM roofing systems perform reliably in virtually any climate.

In East Tennessee, where the climate swings from humid summers to occasional ice storms, EPDM roofing’s elasticity and waterproof properties make it ideal for long-term roof protection. Choosing the right Knoxville roofing contractor ensures you get proper installation and maximum lifespan out of your EPDM system.

Key Takeaways

💡EPDM roofing lasts 30–50 years with routine maintenance.

💡Ideal for flat and low-slope commercial roofs.

💡Weatherproof against rain, UV, hail, ice, and wind.

💡White EPDM options help reduce energy costs in warm climates.

What Is EPDM Roofing?

EPDM roofing is a single-ply rubber membrane made from ethylene, propylene, and diene monomer, which are derived from natural gas and oil. This material is manufactured in large rolls and installed in wide sheets, reducing the number of seams that can potentially leak.

EPDM Roofing Specifications:

| Feature | Details |

|---|---|

| Colors | Black (heat-absorbing) and White (cool roofing) |

| Thickness Options | 45 mil, 60 mil, 75 mil, 90 mil |

| Roll Widths | 10', 20', 50', and custom sizes |

| Standards | Complies with ASTM D4637 |

| Expected Lifespan | 30–50 years with maintenance |

EPDM Roofing Installation Methods

There are three primary ways to install EPDM roofing, each suited for specific building needs:

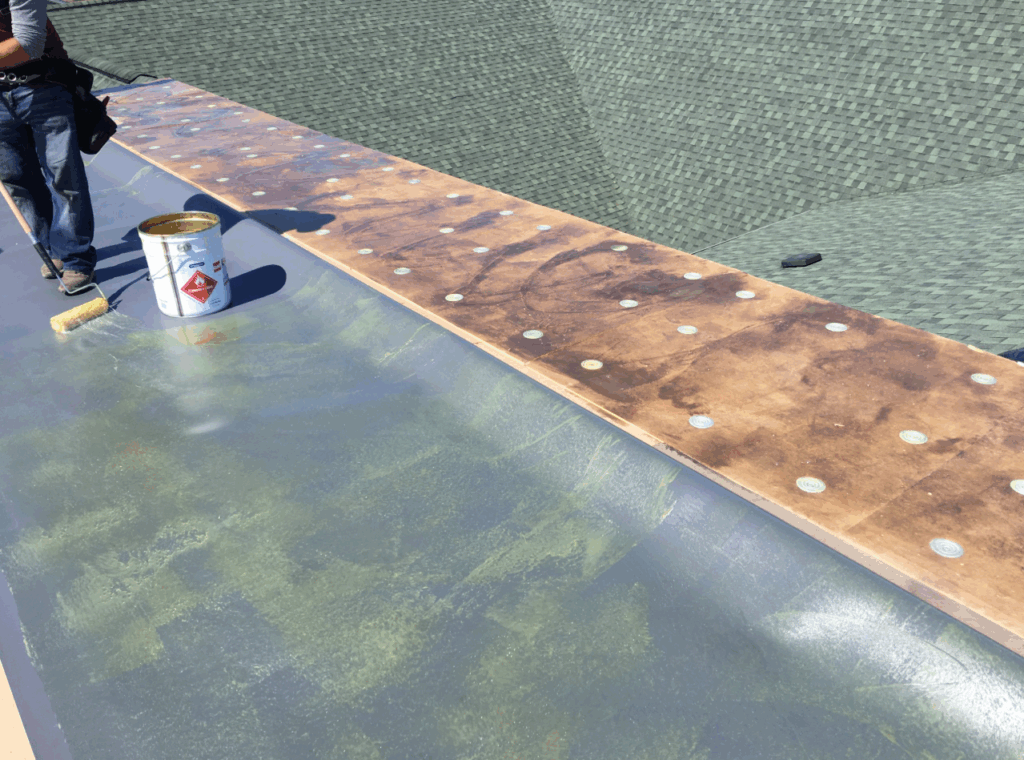

1. Fully Adhered

- Membrane is glued directly to insulation or roof deck

- Ideal for high-wind areas

2. Ballasted

- Membrane is laid loose and secured with heavy stones or pavers

- Suitable for large open roofs

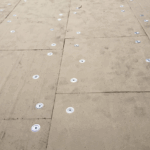

3. Mechanically Fastened

- Attached using fasteners and plates along seams

- Great for metal decking or lightweight structures

Industry Standard: ASTM D4637 — Standard Specification for EPDM Sheet Used in Single-Ply Roof Membrane.

Why EPDM Roofing Performs Nationally

From the humid Southeast to the snowy North, EPDM roofing proves its versatility.

Climate Compatibility Across Regions:

| Region | Climate Challenge | EPDM Solution |

|---|---|---|

| Northeast | Snow loads, freeze-thaw | Remains flexible in freezing temperatures |

| Midwest | Hail storms, UV exposure | Thick membrane resists punctures and UV rays |

| South | High heat, humidity | White EPDM reflects heat, reduces cooling costs |

| Pacific Northwest | Heavy rainfall | Seamless waterproofing resists leaks |

EPDM roofing remains a top national commercial roofing solution, offering consistent performance regardless of regional weather conditions.

Why EPDM Roofing Works Well in Knoxville

Knoxville’s humid subtropical climate presents unique roofing challenges:

- Annual Rainfall: ~50 inches (NOAA)

- Average Summer High: 88°F

- Winter Freeze-Thaw Cycles: 60+ days annually

EPDM’s flexibility allows it to expand and contract without cracking, making it ideal for these conditions. Additionally, its seamless waterproofing helps prevent leaks during heavy storms.

Where Is EPDM Roofing Used?

| Building Type | Why EPDM Works Well | Knoxville Example |

|---|---|---|

| Office Buildings | Low maintenance, clean appearance | Downtown Knoxville offices |

| Warehouses | Large sheets cover big areas with fewer seams | Industrial park roofs |

| Schools | Long lifespan reduces budget strain | Knox County school roofs |

| Hospitals | Reliable leak protection for sensitive areas | Medical centers near UT |

| Retail Centers | Energy efficiency with white EPDM option | West Town Mall annex |

Benefits of EPDM Roofing

1. Durability

With proper maintenance, EPDM roofing lasts three to five decades. It’s resistant to ozone, UV, aging, and weathering.

2. Cost-Effective

Installation costs are lower compared to other single-ply roofing systems like PVC or modified bitumen.

3. Flexibility

Can expand and contract with seasonal temperature swings — ideal for climates with freeze-thaw cycles.

4. Energy Efficiency

White EPDM roofing reflects sunlight, helping reduce HVAC loads and utility bills in hot regions. This reduce cooling loads and help lower Knoxville’s urban heat island effect.

5. Low Maintenance

Fewer seams = fewer opportunities for leaks. Repairs are simple, fast, and usually inexpensive.

6. Eco-Friendly

EPDM is recyclable at end-of-life and has a low environmental footprint during manufacturing compared to some roofing systems.

EPDM Roofing: Pros and Cons

| Pros | Cons |

|---|---|

| ✅ Lifespan of 30–50 years | ❌ Black EPDM may absorb excess heat in hot climates |

| ✅ Affordable installation and repairs | ❌ Can be punctured by sharp objects |

| ✅ Simple to repair with patches or sealant | ❌ Seams require professional sealing |

| ✅ Weather, UV, and ozone resistant | ❌ Not aesthetically pleasing for visible residential roofs |

| ✅ Energy-saving white option available | ❌ Ballasted systems are heavier |

EPDM Roofing Costs (Nationwide)

Cost depends on size, thickness, and installation method.

| Roof Size | Typical Installed Cost per Sq. Ft. | Total Estimate |

|---|---|---|

| 1,000 sq. ft. | $5.00 – $7.00 | $5,000 – $7,000 |

| 5,000 sq. ft. | $4.50 – $6.50 | $22,500 – $32,500 |

| 10,000 sq. ft. | $4.25 – $6.25 | $42,500 – $62,500 |

| 20,000+ sq. ft. | $4.00 – $6.00 | $80,000 – $120,000 |

Reference: National Roofing Contractors Association, regional contractor estimates.

💡 Tip: Choosing thicker membranes (60+ mils) increases lifespan and reduces long-term repair costs.

Real-World Case Studies

Knoxville Case Study 1

Client: Distribution center in Maryville, TN

Roof Size: 120,000 sq. ft.

Old System: TPO with frequent seam failures

Solution: 60-mil white EPDM, fully adhered

Results:

- 40% reduction in cooling energy use

- Zero leaks in 18 months

- Maintenance savings of $8,500/year

Knoxville Case Study 2

Client: Distribution warehouse in East Knoxville

Roof Size: 52,000 sq. ft.

Problem: Frequent leaks with old built-up roof

Solution: Installed 60-mil black EPDM fully adhered system

Result:

- Reduced leaks to zero

- annual HVAC cooling cost dropped 12%

Maintenance Tips for EPDM Roofing

- Annual Inspection — Check after storms or temperature extremes

- Clear Debris — Avoid punctures and drainage issues

- Check seams, seals & flashing — Inspect seams and flashing regularly

- Schedule professional moisture scans — Ensure no hidden leaks.

- Recoat or Patch — Fix minor damage before it becomes a major repair

EPDM Roofing Compared to Alternatives

| Roofing Type | Avg. Lifespan | Cost/Sq. Ft. | Energy Efficient | Maintenance | Fire Resistance |

|---|---|---|---|---|---|

| EPDM Roofing | 30–50 years | $4–$7 | ✅ Yes (white version) | ✅ Low | ✅ High |

| TPO Roofing | 15–30 years | $5–$8 | ✅ Excellent | ✅ Moderate | ✅ High |

| PVC Roofing | 20–30 years | $6–$10 | ✅ Very High | ❌ Can crack | ✅ High |

| Modified Bitumen | 15–25 years | $5–$8 | ❌ Low | ❌ High | ✅ Moderate |

FAQs About EPDM Roofing

EPDM stands for Ethylene Propylene Diene Monomer, a synthetic rubber compound used in commercial roofing.

Typically 30–50 years with regular inspections and maintenance.

EPDM offers superior flexibility, while TPO reflects more heat. Best choice depends on building needs.

Yes, if the current roof is structurally sound.

Yes, especially for flat or low-slope sections like porches, garages, or contemporary flat-roof homes.

Yes, if the current roof structure is sound and meets code requirements.

Thicker EPDM membranes (60+ mils) provide excellent resistance to punctures and hail impact.

Yes, but foot traffic should be minimized and walk pads installed in high-traffic areas.

Yes, it’s recyclable and has a low manufacturing footprint. White EPDM also helps reduce urban heat.

Typically with tape, seam sealant, or patch kits — most repairs are fast and cost-effective.

Licensed commercial roofing contractors with expertise in single-ply membrane systems.

Final Thoughts

EPDM roofing is a proven, cost-effective solution for Knoxville’s commercial and industrial buildings. With its durability, weather resistance, and ease of maintenance, it’s no surprise that EPDM has remained a top choice for decades.

If you’re considering EPDM roofing for your building, contact Litespeed Construction — Knoxville’s trusted roofing contractor — for expert installation, inspection, and maintenance.