In the commercial roofing world, low‑slope roofs dominate the landscape due to their cost-effectiveness, ease of maintenance, and architectural efficiency. Whether it’s a retail space, industrial warehouse, or office complex, buildings with low-slope or flat roofs rely heavily on membrane systems to keep interiors dry and energy bills low.

Litespeed Construction, a trusted Knoxville, TN-based commercial roofing contractor, has served hundreds of property managers and business owners in selecting and installing the ideal low‑slope commercial roof membrane for their specific needs. As climate patterns change and roofing technologies evolve, understanding your membrane options is more important than ever.

Key Takeaways

💡TPO, PVC, EPDM, and Modified Bitumen are the most common low-slope commercial roof membranes.

💡Each membrane offers unique benefits in cost, durability, energy efficiency, and climate adaptability.

💡Proper installation and maintenance can extend membrane life to 20+ years.

💡Litespeed Construction provides tailored roofing solutions based on climate, usage, and budget.

What Is a Low‑Slope Commercial Roof Membrane?

A low-slope commercial roof membrane is a single-layer or multi-layer protective material applied to flat or low-angle rooftops to prevent water infiltration, regulate temperature, and increase roof longevity.

Unlike steep-slope residential roofs, low-slope systems require membranes that can handle standing water, UV radiation, and thermal movement without the benefit of pitch-driven drainage.

Per the National Roofing Contractors Association (NRCA), a roof is considered low-slope if its pitch is less than 3:12. Membranes used for such roofs are selected for their water-tightness, flexibility, and long-term performance.

Types of Low‑Slope Commercial Roof Membrane Systems

According to the U.S. Department of Energy (DOE), up to 35% of a building’s energy loss can be attributed to poorly insulated or aging roofs—making membrane selection a critical business decision. Here’s a breakdown of the most widely used membranes on commercial low-slope roofs, including their benefits, ideal applications, and expected lifespans.

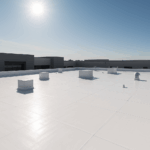

1. TPO (Thermoplastic Polyolefin)

Overview:

TPO is one of the fastest-growing commercial roofing systems in the U.S., known for its white, reflective surface and cost-efficiency.

Benefits:

- High solar reflectivity (reduces energy costs)

- Heat-welded seams for superior waterproofing

- Resistant to UV, ozone, and chemical exposure

Stats:

- Energy Star rated with up to 80% reflectivity

- Average lifespan: 20–30 years

- Installed on over 40% of new commercial roofs in the U.S. (Source: NRCA)

Best For: Office buildings, retail centers, climate zones with high heat exposure

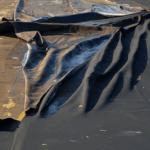

2. EPDM (Ethylene Propylene Diene Monomer)

Overview:

EPDM is a synthetic black rubber membrane known for its durability and performance in variable climates.

Benefits:

- High resistance to hail, UV, and thermal shock

- Lower upfront costs

- Easy repair and maintenance

Stats:

- Lifespan: 25–35 years

- Typically costs $4–$8 per square foot

- Installed on over 20 billion square feet globally (Source: EPDM Roofing Association)

Best For: Industrial facilities, schools, buildings in cold climates

3. PVC (Polyvinyl Chloride)

Overview:

PVC membranes are highly durable, chemical-resistant, and perfect for restaurants or facilities with grease or chemical exposure.

Benefits:

- Superior chemical and grease resistance

- Fire-resistant and recyclable

- Available in light-reflective colors

Stats:

- Lifespan: 20–30 years

- Energy savings up to 40% compared to dark-colored roofs (DOE)

- Ideal for restaurants and manufacturing plants

Best For: Commercial kitchens, manufacturing plants, medical centers

4. Modified Bitumen

Overview:

This asphalt-based membrane system is reinforced with fiberglass or polyester and applied in multiple plies for enhanced protection.

Benefits:

- Time-tested durability

- Excellent waterproofing in high-rainfall regions

- Can be applied with hot-mop, torch-down, or cold adhesives

Stats:

- Lifespan: 15–25 years

- Average cost: $3–$6 per square foot

- NRCA ranks it as a top choice for budget-conscious businesses

Best For: Warehouses, older buildings, budget-sensitive projects

Comparison Table: Roof Membrane Options

| Membrane Type | Lifespan (Years) | Cost/Sq. Ft. | Reflectivity | Best Use Case | Fire/Grease Resistance |

|---|---|---|---|---|---|

| TPO | 20–30 | $5–$9 | High | Retail, offices, hot climates | Moderate |

| EPDM | 25–35 | $4–$8 | Low | Industrial, cold climates | Low |

| PVC | 20–30 | $6–$10 | High | Restaurants, chemical facilities | High |

| Modified Bitumen | 15–25 | $3–$6 | Moderate | Budget-conscious, older buildings | Moderate |

Pros and Cons of Low‑Slope Commercial Roof Membranes

✅ Pros

- Energy Efficient: Reflective membranes like TPO and PVC reduce cooling costs.

- Durability: Membranes can last over 30 years with proper care.

- Customizable: Systems can be tailored to resist specific threats (UV, chemicals, etc.).

- Eco-Friendly: Many systems are recyclable or ENERGY STAR certified.

❌ Cons

- Installation Sensitive: Requires expert installers to prevent seam leaks or blisters.

- Higher Initial Cost: Some premium membranes can be expensive upfront.

- Vulnerable to Punctures: Single-ply systems like TPO and PVC can be damaged by foot traffic.

Knoxville's Climate & Roof Membrane Suitability

Knoxville’s humid subtropical climate—with hot summers and moderate winters—demands roof membranes that can handle both thermal expansion and UV radiation. Here’s how each membrane ranks for Knoxville:

- TPO: Ideal due to its reflectivity and heat resistance.

- EPDM: Good choice, but may absorb more heat in summer.

- PVC: Excellent for facilities handling chemicals or grease.

- Modified Bitumen: Economical and proven for older buildings.

Why Choose Litespeed Construction?

Litespeed Construction is a licensed, insured, and highly rated commercial roofing contractor based in Knoxville, TN. With over a decade of experience in installing and maintaining low-slope commercial roof membranes, the team is recognized for:

- Fast and accurate estimates

- Expert installations that meet manufacturer and warranty guidelines

- Excellent customer service and transparent pricing

- Maintenance packages to extend roof life and prevent issues

FAQs about Low-Slop Commercial Roofs

EPDM and PVC membranes tend to last the longest—up to 35 years with proper care.

Modified bitumen offers the lowest upfront cost per square foot.

TPO is more affordable and energy-efficient, but PVC resists chemicals better.

Yes, most offer 10–30 year warranties depending on installation and material.

At least twice a year and after major weather events.

Yes. TPO and PVC are commonly used under solar arrays due to their reflectivity.

Yes, hot summers favor reflective membranes like TPO and PVC.

Ponding water is stagnant water on a flat roof—membranes must be designed to resist it, and proper drainage is key.

PVC offers the highest fire resistance among membrane options.

Visit Litespeed Construction’s website or call to schedule a free commercial roof inspection in Knoxville, TN.