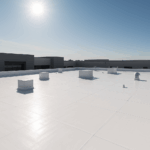

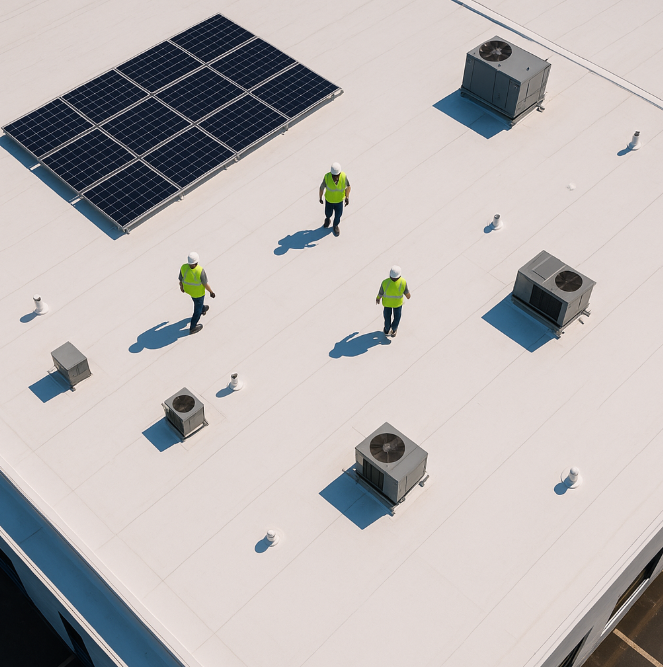

A commercial roof isn’t just a structural necessity—it’s a critical investment. Yet, many property owners neglect one of the most important aspects of ownership: how to clean and maintain commercial roof membranes.

Membrane roofs—especially TPO, EPDM, and PVC systems—are common on commercial buildings across the U.S. for their durability and energy efficiency. However, the National Roofing Contractors Association (NRCA) and U.S. Department of Energy (DOE) warn that without regular maintenance, these roofs can deteriorate faster, leading to expensive repairs or even total replacements.

Litespeed Construction, a Knoxville, TN-based commercial roofing leader, specializes in the maintenance, cleaning, and repair of commercial roofing systems nationwide. This guide breaks down everything you need to know to protect your investment and reduce lifecycle costs.

Key Takeaways

💡Routine Maintenance Prevents Major Repairs

💡Annual Inspections Are Non-Negotiable

💡Membrane Type Dictates Cleaning Method

💡Pro Maintenance Boosts Lifespan by 30-40%

Types of Commercial Roof Membranes & Their Maintenance Needs

| Membrane Type | Common Material | Lifespan (Years) | Maintenance Frequency | Susceptible Issues |

|---|---|---|---|---|

| TPO | Thermoplastic Polyolefin | 15-30 | Every 6 months | UV damage, punctures |

| EPDM | Synthetic Rubber | 20-25 | Annual | Shrinkage, seam separation |

| PVC | Polyvinyl Chloride | 15-25 | Every 6 months | Brittle cracking, chemical damage |

| Modified Bitumen | Asphalt-based | 10-20 | Annual | Blistering, UV degradation |

| Built-Up Roofing (BUR) | Asphalt + Gravel | 15-30 | Annual | Moisture intrusion, ponding water |

Sources: DOE Roof Maintenance Guide, NRCA Guidelines

Step-by-Step: How to Maintain Commercial Roof Membranes

1. Perform a Thorough Inspection

Every maintenance routine should begin with a detailed inspection:

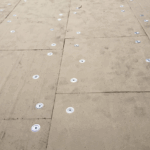

- Visual inspection for cracks, punctures, and membrane uplift

- Check drainage systems for clogs and blockages

- Inspect seams and flashing for signs of separation or wear

✅ Pro Tip: Use infrared scanning to detect hidden moisture.

2. Clean the Surface Properly

Depending on the roof type, choose the appropriate method:

TPO and PVC Membranes:

- Use a low-pressure washer (≤ 2,000 PSI)

- Apply non-abrasive, biodegradable cleaners

- Avoid solvents that can break down polymer bonds

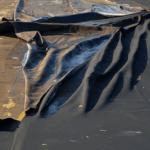

EPDM Membranes:

- Only use soft brooms or low-pressure hoses

- Avoid any petroleum-based cleaning agents

- Apply EPDM-safe membrane cleaner recommended by manufacturer

3. Address Repairs Immediately

After cleaning, patch minor holes or tears using manufacturer-approved materials. Avoid DIY sealing kits which may void warranties.

4. Reseal Seams and Flashings

Reinforce or reseal aging seams and penetrations using heat welders (TPO/PVC) or adhesive tapes (EPDM).

5. Schedule Preventive Maintenance Twice a Year

According to the International Facility Management Association (IFMA), bi-annual maintenance reduces the likelihood of costly repairs by 70%.

📍 Litespeed Construction offers customized preventive maintenance programs for businesses in Knoxville and beyond.

Key Statistics: Why Maintenance is Non-Negotiable

| Maintenance Benefit | Stat or Fact | Source |

|---|---|---|

| Increases roof lifespan | +30-40% | DOE |

| Reduces leak-related downtime | -85% | IFMA |

| Saves average building owner $0.11/sq ft annually | Cost Savings | Building Operating Management |

| Average commercial roof replacement cost | $8.00 - $14.00/sq ft | RSMeans Data |

Common Problems from Lack of Maintenance

Neglecting to maintain commercial roof systems can result in:

- Mold growth

- Structural water damage

- Energy inefficiency

- Voided manufacturer warranties

- Compliance violations

According to the Environmental Protection Agency (EPA), indoor air quality suffers when commercial roofs harbor mold and mildew—impacting both worker health and productivity.

Pros and Cons of Maintaining Commercial Roof Membranes

| Pros | Cons |

|---|---|

| Extends lifespan of the roof | Requires scheduled access to rooftop |

| Reduces total cost of ownership | Upfront maintenance costs |

| Maintains warranty coverage | Needs professional expertise |

| Prevents leaks and energy loss | Weather-dependent timing |

FAQs About How to Maintain Commercial Roof Membranes

Twice a year—ideally in spring and fall—to remove debris, mold, and pollutants.

Biodegradable, non-acidic roof membrane cleaners like GacoWash or Simple Green Pro HD.

Yes, but only with a low-pressure washer (under 2,000 PSI). Higher pressure can damage seams.

Discoloration, pooling water, mold growth, and visible debris accumulation.

Typically not, but neglecting to clean can void the warranty.

Yes, reflective membranes lose efficiency when dirty. Cleaning improves reflectivity and reduces HVAC load.

Mold can infiltrate HVAC systems, degrading indoor air quality and violating OSHA regulations.

2–6 hours depending on roof size and dirt level.

$0.15 to $0.50 per sq ft, based on roof type, dirt levels, and accessibility.

Basic cleaning is possible, but inspections and repairs should be done by licensed professionals like Litespeed Construction.

Want to Keep Your Roof in Peak Condition?

Litespeed Construction offers countywide service with a stronghold in Knoxville, TN. Our certified team specializes in:

- Scheduled inspections

- Membrane cleaning

- Leak detection and repair

- Roof asset management reports

Final Thoughts

To maintain commercial roof membranes properly, property owners need a reliable, knowledgeable partner. With decades of experience, Litespeed Construction has the tools, expertise, and commitment to protect your investment and keep your roof performing for decades.

👉 Contact us today for a free consultation or maintenance quote. Protect your building, your budget, and your peace of mind.