When it comes to commercial roofing, one of the most crucial yet overlooked components is commercial roof flashing. Flashing serves as the first line of defense against water intrusion—sealing vulnerable joints, edges, and penetrations to protect the building beneath.

If you’re a property manager, facility director, or business owner, the materials you choose for your roof flashing can determine your building’s longevity, energy efficiency, and maintenance costs over time.

At Litespeed Construction, Knoxville’s leading commercial roofing company, we’ve seen first-hand how the right flashing choice can save thousands in repairs and reduce energy bills significantly.

Key Takeaways

💡Flat roofs in hot, humid climates (like Knoxville, TN) perform best with flexible, UV-resistant flashing materials.

💡Flashing materials must meet IBC (International Building Code) and NRCA (National Roofing Contractors Association) standards.

💡Investing in high-quality flashing can extend the life of your commercial roof by 10–15 years.

What Is Commercial Roof Flashing?

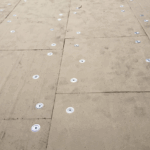

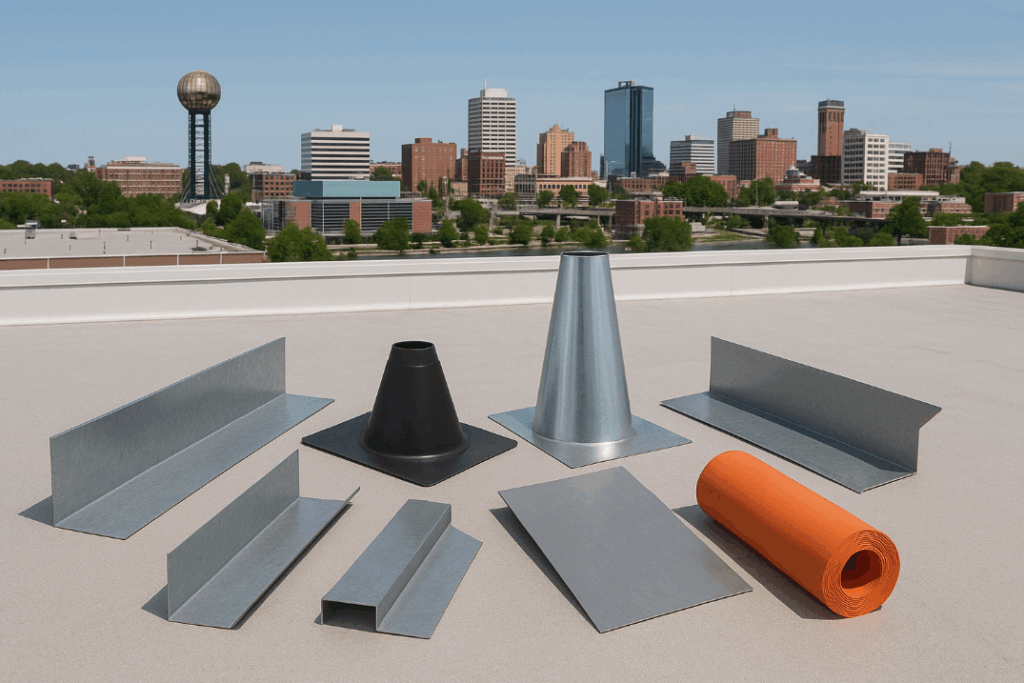

Commercial roof flashing is a weatherproofing barrier installed around seams, joints, and roof penetrations (vents, HVAC systems, skylights, etc.). Its job is to redirect water away from vulnerable areas and prevent leaks.

Unlike residential roofs that are often pitched, commercial roofs are usually flat or low-slope, making them more susceptible to standing water. This makes flashing even more critical.

Types of Commercial Roof Flashing Materials

Choosing the right material is a balancing act between cost, durability, ease of installation, and local climate conditions.

| Material Type | Lifespan (Years) | Cost ($/ft²) | Pros | Cons |

|---|---|---|---|---|

| Aluminum | 15–25 | $1.50–$3.00 | Lightweight, corrosion-resistant | Dents easily, may react with some roofing membranes |

| Galvanized Steel | 20–30 | $1.00–$2.50 | Strong, affordable | Prone to rust over time without coating |

| Copper | 50+ | $6.00–$12.00 | Extremely durable, antimicrobial | High upfront cost |

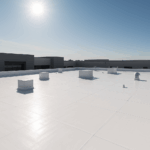

| TPO (Thermoplastic Polyolefin) | 20–30 | $1.00–$3.00 | Heat-weldable, energy-efficient | Requires professional installation |

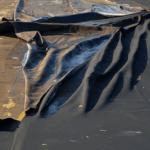

| EPDM (Ethylene Propylene Diene Monomer) | 20–25 | $0.80–$2.00 | Flexible, UV-resistant | Vulnerable to punctures |

Factors to Consider When Choosing Commercial Roof Flashing

1. Building Type and Function

- For medical facilities or data centers, long-lasting flashing like copper may be worth the investment.

- Warehouses and retail stores may opt for TPO or galvanized steel for affordability.

2. Roof Design

- Flat roofs need membrane-compatible flashing (TPO, EPDM).

- Sloped commercial roofs can handle metal flashing more easily.

3. Knoxville’s Climate Conditions

- Hot summers, moderate to high rainfall, and UV exposure call for UV- and corrosion-resistant materials like EPDM and TPO.

4. Energy Efficiency Goals

- White TPO flashing reflects sunlight, reducing cooling loads.

- ENERGY STAR-rated flashing systems can qualify for federal tax credits and rebates.

5. Building Code Compliance

- Ensure materials meet ASTM D1970 and IBC 1503.2 codes for water resistance and flashing performance.

🔍 Tip: Always request material certifications from your roofer or contractor to ensure compliance.

Building Code & Industry Standards to Know

| Standard | Description |

|---|---|

| IBC (International Building Code) | Requires flashing to be corrosion-resistant and sealed to prevent water entry. |

| ASTM D1970 | Standard spec for self-adhering flashing used to prevent water intrusion. |

| NRCA Guidelines | Best practices for flashing installation on commercial buildings. |

| LEED Certification | Credits available for energy-efficient roofing materials, including flashing. |

📌 Reference: ICC IBC Chapter 15, ASTM International

Web Ratings of Top Flashing Materials (By Experts)

| Material | Durability | Energy Efficiency | Maintenance | Cost Efficiency | Avg. Rating (5) |

|---|---|---|---|---|---|

| Copper | ⭐⭐⭐⭐⭐ | ⭐⭐⭐⭐ | ⭐⭐⭐⭐⭐ | ⭐⭐ | 4.6 |

| TPO | ⭐⭐⭐⭐ | ⭐⭐⭐⭐⭐ | ⭐⭐⭐⭐ | ⭐⭐⭐⭐ | 4.5 |

| EPDM | ⭐⭐⭐⭐ | ⭐⭐⭐ | ⭐⭐⭐⭐ | ⭐⭐⭐⭐ | 4.3 |

| Galvanized Steel | ⭐⭐⭐⭐ | ⭐⭐ | ⭐⭐⭐ | ⭐⭐⭐⭐ | 4.1 |

| Aluminum | ⭐⭐⭐ | ⭐⭐ | ⭐⭐ | ⭐⭐⭐⭐ | 3.9 |

Why Choose Litespeed Construction for Your Commercial Flashing?

- Local expertise in Knoxville’s unique climate

- Fully licensed and insured commercial roofing contractors

- Over 12 years of experience

- Proven track record with hospitals, schools, warehouses, and retail centers

- Use of premium materials backed by manufacturer warranties

📞 Call us today at (865) 297-3286 for a free commercial roof inspection!

FAQs about Commercial Roof Flashing

To direct water away from vulnerable areas of the roof, preventing leaks and structural damage.

At least twice a year, and after major storms or roof repairs.

Not recommended—commercial roofs require different standards and materials due to size and design.

TPO or EPDM, due to their flexibility and waterproofing abilities.

Depending on the material—between 15 to 50+ years.

Yes. All commercial roof alterations, including flashing, require permits per Knoxville-Knox County Codes Department.

Often, yes—but only when installed correctly and using approved materials.

Yes, but the paint must be UV- and weather-resistant to avoid degradation.

Regular inspections, keeping joints sealed, and clearing debris to avoid ponding water.

Anywhere between $2–$12 per linear foot, depending on material and complexity.

Protect Your Investment with the Right Flashing

Choosing the right commercial roof flashing is not just about compliance—it’s about longevity, safety, and financial peace of mind. For Knoxville businesses, investing in quality flashing materials tailored to the local climate is a decision that pays dividends for decades.

And with a trusted partner like Litespeed Construction, you can rest easy knowing your commercial roof is in expert hands.