Commercial Roof Replacement Specifications

Time to replace your commercial roof?

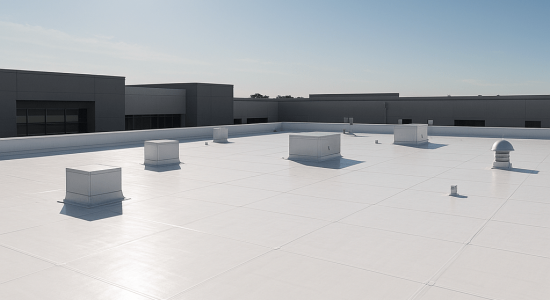

Think of a commercial roof replacement like buying your building a brand‑new hat with insulation lining: it keeps the weather out, adds style and comfort, and if you pick the wrong one you could end up with a wet head and a big headache. It’s a major investment that affects the safety, energy efficiency and longevity of a building, and it’s not as simple as ripping off an old membrane and slapping on a new one. On the contrary, a proper replacement involves understanding drainage, membrane types and insulation requirements—three ingredients that make the difference between a roof that performs and one that puddles. For Knoxville businesses in climate zone 4, commercial roof replacement decisions must consider heavy rain events, humidity and the International Energy Conservation Code (IECC) requirements.

Key Takeaways

💡Positive roof drainage prevents structural failure.

💡Membrane selection affects durability and energy efficiency.

💡Proper insulation saves energy and meets code.

💡Knoxville’s mixed‑humid climate and rising heavy rainfall require robust drainage and insulation levels.

Want to talk to a roofer?

Drainage in Commercial Roof Replacement

Why Drainage Matters

Water is the enemy of roofs—and unlike those chic rooftop pools at boutique hotels, ponding water on a commercial building isn’t a selling point. When a roof lacks adequate slope or drainage, rainwater accumulates into little lakes that load the structure, deteriorate the membrane and shorten its service life. The Roofing Contractor magazine warns that the most serious defect of standing water is structural damage—ponded water adds load to the roof and can cause collapse. Moisture that remains on the surface also leaches oils from bitumen and reduces membrane thickness, increasing the risk of leaks. Because wet insulation loses thermal performance, ponding also undermines energy efficiency. A commercial roof replacement must therefore prioritise drainage design; there’s nothing funny about a roof that doubles as a fish pond.

Minimum Slope Requirements

One expectation of this allows existing roofs to meet code if positive drainage is provided but emphasises that inadequate slope leads to water accumulation and potential collapse. Duke University’s construction standards specify that the slope to drainage outlets shall be a minimum of ¼ inch per foot and should be incorporated into the structural deck facilities. They recommend using crickets (small tapered insulation shapes) at curbs and penetrations to divert water, with cricket slopes twice the roof slope.

📊 Table 1: Minimum Slope Requirements for Commercial Roof Drainage

| Roof Type/System | Minimum Slope Requirement | Notes |

|---|---|---|

| General Low-Slope Roof (IBC) | ¼ inch per foot (2%) | Required to achieve drainage within 48 hours |

| Smooth-Surface Roof Systems | ½ inch per foot (4%) | Required for better water shedding due to surface texture |

| Cricket Slope (at curbs/penetrations) | Twice the roof slope | Enhances diversion around obstructions |

| Maximum Deck Deflection | 1/240 of roof span | Example: 2.5" max deflection on a 50-ft span |

Positive slopes between ¼ inch and ½ inch per foot are common, with smooth‑surface systems requiring ½ inch per foot. During commercial roof replacement, Knoxville roofing contractors should correct existing deck slopes or install tapered insulation to achieve these requirements—if the water won’t slide off, your roof isn’t doing its job.

Designing Drainage Systems

Drainage design involves more than slope; it’s the plumbing equivalent of choreography. Deck deflection, drain placement and system type influence how water leaves the roof:

- Slope and deflection: Deck deflection must be limited to no more than 1/240 of the roof span. For a 50‑ft span, deflection should not exceed 2½ inches. Drains should be located at mid‑span (points of maximum deflection); placing drains at columns or bearing walls can require steeper slopes to compensate.

- Peripheral vs. interior systems: Peripheral systems allow water to run off the edge through scuppers and gutters; they work well in mild climates but are vulnerable to ice in cold climates—think of them like open‑toed shoes in winter. Interior systems use roof drains connected to interior piping; because pipes are heated, they function year‑round. Knoxville’s freeze–thaw cycles favour interior drains for commercial roof replacement .

- Peripheral vs. interior systems: Peripheral systems allow water to run off the edge through scuppers and gutters; they work well in mild climates but are vulnerable to ice in cold climates—think of them like open‑toed shoes in winter. Interior systems use roof drains connected to interior piping; because pipes are heated, they function year‑round. Knoxville’s freeze–thaw cycles favour interior drains for commercial roof replacement .

- Number and spacing of drains: To ensure positive drainage, designers should provide two drains for roofs under 10,000 sq ft and add one drain for each additional 10,000 sq ft. Drains should be spaced no more than 75 feet apart, except around obstructions. Professional commercial roofers typically recommend at least two drains per major roof section and spacing drains no more than 40 feet apart to prevent ponding.

- Drain patterns: An “inverted pyramid” pattern—placing drains at the center of rectangular roof bays with four‑way slope—provides consistent drainage. Tapered insulation or structural framing can create this pattern. Drains should sit slightly below the roof surface with sumps and tapered insulation around them. Overflow drains or scuppers must be on separate lines from primary drains to handle blocked drains. When scuppers serve as secondary drainage, they should be 2–4 inches above the roof level. Explore more about drain patterns and tapered insulation design here.

- Crickets and penetrations: Crickets are triangular tapered insulation panels that divert water around curbs, skylights and HVAC units.Typical standards require crickets with slopes twice the roof slope around penetrations. We also avoid placing drains near base flashings or walls, as the water can attack seams.

In summary, proper drainage design—adequate slope, structural considerations, drain layout and secondary drainage—is essential for a safe and durable commercial roof replacement.

🌧️ Table 2: Drainage Design Specifications Based on Roof Size

| Roof Area (sq ft) | Min. # of Primary Drains | Drain Spacing (ft) | Overflow Drain Height Above Roof | Notes |

|---|---|---|---|---|

| 0–10,000 | 2 | ≤40–75 | 2–4 inches | Minimum standard per Duke + IBC guidelines |

| 10,001–20,000 | 3 | ≤40–75 | 2–4 inches | Add 1 drain per 10k sq ft |

| 20,001–30,000 | 4 | ≤40–75 | 2–4 inches | Scuppers or drains must be separate lines |

Membrane Types in Commercial Roof Replacement

Selecting the right membrane is critical to commercial roof replacement because the membrane provides waterproofing and affects durability, energy performance and maintenance. Think of the membrane as a superhero cape for your building—you want one that’s tough, flexible and suited to the villain your building faces, whether it’s UV rays, chemical fumes or constant foot traffic. This section outlines the main options: thermoplastic single‑ply membranes (PVC and TPO), synthetic rubber (EPDM), built‑up roofing (BUR), and modified bitumen systems. Each type has unique properties, benefits and considerations for commercial roof replacement .

Thermoplastic Single‑Ply Membranes

Thermoplastic membranes soften when heated and harden when cooled, allowing seams to be heat‑welded. They are generally lightweight and come in rolls that cover large areas, reducing seams and labour. Common thermoplastic membranes used in commercial roof replacement are PVC and TPO.

Polyvinyl Chloride (PVC)

PVC membranes have the longest track record of thermoplastic roofs; the first PVC systems were installed in Europe in the early 1960s. PVC membranes contain reinforcement (polyester or fiberglass) along with vinyl resins, ultraviolet inhibitors, heat stabilisers, biocides, pigments and plasticizers.

Reinforcement provides high tear and breaking strength for mechanically fastened systems. Vinyl is inherently self‑extinguishing, enabling PVC membranes to achieve fire ratings from Underwriters Laboratories and Factory Mutual. However, plasticizers are added to impart flexibility, and past failures occurred when plasticizers migrated out of un‑reinforced membranes. Modern PVC membranes are reinforced and formulated to minimise plasticizer loss. They come primarily in white or light colours, which helps create cool roofs with high reflectance.

For commercial roof replacement, PVC offers excellent chemical resistance and heat‑welded seams but may cost more than other membranes. Because plasticizers can still migrate over time, periodic inspection (at least once per year and after heavy storms) is recommended.

Manufacturer Insights for PVC

When evaluating PVC membranes for commercial roof replacement , it helps to compare offerings from leading manufacturers. GAF’s EverGuard® PVC smooth membrane is engineered for long‑term performance and features a highly reflective and emissive white surface that can reduce cooling loads and mitigate urban heat island effects. GAF provides warranties of up to 30 years for qualified PVC systems, demonstrating confidence in their durability. The company highlights additional benefits such as increased protection against chemicals compared with other single‑ply materials, easy installation using prefabricated accessories and 10‑foot‑wide sheets, and high flexibility that allows the membrane to conform to complex roof contours. GAF also offers PVC KEE membranes that use a solid ketone‑ethylene‑ester polymer instead of liquid plasticizers; this solid plasticizer resists dirt pickup and mold or mildew growth and is often specified for applications involving grease, animal fats or jet fuel.

By specifying premium PVC membranes from manufacturers like GAF, building owners can enhance chemical resistance, ease installation and obtain long warranty periods—key considerations when planning a durable commercial roof replacement.

Thermoplastic Polyolefin (TPO)

TPO membranes have gained popularity in the past decade. TPO is manufactured by polymerising polypropylene and ethylene‑propylene rubber. This manufacturing technology allows TPO to remain flexible at low temperatures without the use of liquid plasticizers. Unlike PVC, TPO contains no chlorine, reducing environmental concerns. The TPO resin is compounded with a weathering package, fire retardants and pigments to withstand rooftop exposure. Because TPO is not inherently fire‑resistant, adequate fire retardants must be included.

TPO membranes are typically white or light‑coloured, offering high reflectance and energy savings in hot climates. For commercial roof replacement , TPO can be mechanically fastened or fully adhered, with seams heat‑welded for watertight integrity. However, TPO formulations vary by manufacturer; quality and fire resistance depend on the ratio of weathering materials and fire retardants. Building owners should work with experienced commercial roofing contractors like Litespeed Construction to choose high‑quality TPO.

Manufacturer insights for TPO

Because TPO formulations vary, reviewing manufacturer data sheets helps ensure quality. GAF’s EverGuard® TPO membranes have remained essentially unchanged for decades; the company reports selling more than 6 billion square feet of EverGuard® TPO and highlights that the membrane offers flexibility, durability, UV reflectivity and heat‑sealable seams without relying on plasticizers. EverGuard® is available in 45‑, 60‑ and 80‑mil thicknesses, and GAF provides guarantees up to 20 years for 45‑mil, 25 years for 60‑mil and 30 years for 80‑mil systems. GAF also offers 12‑foot‑wide rolls to reduce seams and labour and optional MembraneShield temporary dirt‑blocking film to keep the membrane clean during installation.

Carlisle SynTec’s Sure‑Weld® TPO features the OctaGuard XT weathering package, which allows the membrane to withstand high temperatures, UV radiation and various weather conditions. Carlisle offers TPO membranes up to 80 mil thick with warranties of up to 30 years, along with a range of colours—three standard and five specialty colors—and system options that include mechanically fastened, fully adhered and induction‑welded assemblies. These membranes boast high reflectivity and strong heat‑welded seams, making them suitable for diverse building types.

Johns Manville (JM) TPO membranes incorporate a reinforced fabric scrim and an optimised formulation for ozone resistance, cool‑roof reflectivity and overall weather resistance. JM emphasizes its “wide melt window,” which permits heat‑welded seams to be achieved over a broader range of temperatures and speeds, resulting in a softer, more workable sheet. The membranes are available in multiple widths and colors and have initial solar reflectance values up to 0.77 and emissivity values around 0.87. JM offers guarantee terms ranging from 5 to 20 years, depending on the membrane thickness and system configuration.

Selecting a high‑quality TPO from these manufacturers can improve long‑term performance. Litespeed Construction works with top brands like GAF, Firestone, Carlisle and Johns Manville to ensure each commercial roof replacement in Knoxville meets the owner’s performance, budget and warranty requirements.

Synthetic Rubber (EPDM)

Ethylene‑propylene‑diene monomer (EPDM) is a thermoset membrane—once cured, it cannot be re‑melted. EPDM membranes are seamed using adhesives or tapes rather than heat‐welding. Tapes have become standard because they are easier to install and reduce installation error. EPDM rolls can be as wide as 10 feet, resulting in fewer seams. The membrane’s elasticity allows it to stretch and relax, accommodating thermal expansion and contraction on large roofs. EPDM systems have been used for more than 30 years; enhancements include reinforcement and new seaming methods.

EPDM is typically black, which absorbs heat, but white EPDM membranes and acrylic coatings can improve reflectance. For commercial roof replacement, EPDM offers durability and flexibility but may require additional ballast or mechanical fasteners. Because seams rely on adhesives, proper substrate preparation is vital.

Built‑Up Roofing (BUR)

Built‑up roofing is one of the oldest low‑slope systems. The U.S. General Services Administration defines a built‑up roof as “a continuous roof covering made up of laminations or plies of saturated or coated roofing felts, alternated with layers of asphalt or coal‑tar pitch and surfaced with a layer of gravel or slag or finished with a cap sheet”. A typical BUR consists of three or more plies of roofing felt set in hot asphalt, producing a thick, redundant waterproofing assembly. The surface is protected by gravel or a mineral cap sheet to shield the membrane from ultraviolet light and weathering.

BUR advantages include proven performance, high puncture resistance and redundancy—if one ply is damaged, others remain intact. BUR’s heavy weight enhances wind resistance. However, the hot asphalt installation is labour‑intensive, has odour and smoke, and requires skilled roofers. BUR may also be susceptible to cracking or alligatoring over time. For commercial roof replacement , BUR is suitable for buildings requiring robust protection and may be combined with cool roof coatings for improved reflectance. Owners should ensure the roof deck can support the weight and that installation is performed by experienced personnel.

Modified Bitumen Systems

Modified bitumen systems were developed to combine the redundancy of BUR with the flexibility of single‑ply membranes. They use sheets of bitumen modified with polymers—either atactic polypropylene (APP) or styrene‑butadiene‑styrene (SBS)—reinforced with polyester or fiberglass. According to Tremco’s system design guide, modified bitumen roof systems consist of five basic components: insulation to provide R‑value and substrate, modified base sheets or plies, modified bitumen membranes, adhesive (hot or cold applied) and surfacing. The surfacing (mineral granules or coatings) provides ultraviolet protection. Modified bitumen membranes offer features such as resistance to thermal shock, superior fire resistance and the ability to customize the system to specific needs.

Modified bitumen systems can be configured as two‑ply or multi‑ply assemblies; self‑adhered options reduce odour and safety concerns. For commercial roof replacement , modified bitumen offers an excellent balance of durability and ease of installation. Litespeed Construction can recommend SBS or APP systems based on building use, budget and climate.

📊 Table 3: Comparison of Commercial Roof Membrane Types

| Membrane Type | Fire Resistance | UV Resistance | Cost | Seaming Method | Cool Roof Potential | Chemical Resistance | Ideal For |

|---|---|---|---|---|---|---|---|

| PVC | High | Excellent | $$$ | Heat-welded | High (white) | Excellent | Labs, kitchens, refineries |

| TPO | Moderate–High | High | $$ | Heat-welded | High (white) | Moderate | Retail, warehouses |

| EPDM | Moderate | Moderate | $ | Tapes/Adhesive | Low (unless coated) | Moderate | Offices, cold climates |

| BUR | High | High (with gravel) | $$$$ | Asphalt layers | Moderate (w/ coating) | High | Industrial buildings |

| Mod. Bitumen | High | High | $$$ | Torch or cold applied | Moderate | High | Schools, hospitals, low-rise |

Sources: GAF, Carlisle SynTec, Firestone

Choosing the Right Membrane

Membrane selection for commercial roof replacement depends on numerous factors:

- Building Use and Access: Buildings with heavy foot traffic (e.g., roof‑top equipment or maintenance) require robust membranes such as PVC, thick TPO or BUR. Light‑traffic roofs may use single‑ply membranes.

- Chemical Exposure: Restaurants or laboratories may have grease or chemical exhaust; PVC has superior chemical resistance. EPDM and TPO require protective mats or coatings in these environments.

- Energy Efficiency: White TPO or PVC membranes reflect sunlight; cool roofs can reduce roof temperatures by more than 50°F compared with dark roofs. Cool roofs lower energy bills and can extend roof life.

- Budget: EPDM typically has lower material costs; TPO and PVC may have higher initial costs but offer energy savings. BUR and modified bitumen have higher labour costs but long service lives.

- Local Climate: Knoxville’s warm summers and occasional snow demand membranes that handle temperature swings and occasional ice. PVC or TPO with reflective surfaces can reduce cooling loads, while EPDM can withstand freeze–thaw cycles.

Litespeed Construction reviews these factors during commercial roof replacement consultations to recommend the most appropriate membrane.

Insulation in commercial roof replacement

Importance of Insulation

Insulation is a core component of any commercial roof replacement because it reduces heat flow through the roof, stabilises indoor temperatures and lowers energy costs. Imagine wrapping your building in a comfy blanket or putting it in a thermos—without insulation, you’re basically sending money through the roof. The Department of Energy explains that insulation’s thermal resistance (R‑value) depends on type, thickness and density. Adding insulation increases the R‑value and decreases heat flow; for loose‑fill insulation the R‑value does not increase proportionally with thickness because of compression. Proper insulation design helps meet building code requirements, prevents condensation and contributes to occupant comfort.

R‑Value Requirements and Climate Zone 4

The International Energy Conservation Code (IECC) and ASHRAE 90.1 set minimum insulation requirements for commercial roofs. Tennessee follows the 2012 IECC, which requires R‑25 continuous insulation above the roof deck for climate zone 4. However, the Polyisocyanurate Insulation Manufacturers Association (PIMA) notes that current model code requirements are more stringent—R‑25 for climate zone 3 and R‑30 for climate zone 4. PIMA advises building owners to exceed state minimum requirements to improve energy efficiency and reduce operating costs. They also cite the U.S. Department of Energy’s recommendation of R‑25ci (continuous insulation) for climate zone 4.

Litespeed Construction designs commercial roof replacement projects in Knoxville with R‑30 or higher where feasible. Using multiple layers of polyisocyanurate (polyiso) boards can achieve the required R‑value. PIMA’s fact sheet provides example assemblies: two layers of 2.2‑inch polyiso plus a 0.5‑inch high‑density polyiso cover board deliver R‑25.2. For R‑30, polyiso thickness increases to roughly 3 inches, and crickets may be used to maintain drainage slopes.

Types of Roof Insulation

Several insulation materials are used in commercial roof replacement:

1. Polyisocyanurate (Polyiso):

Polyiso is the most common commercial roof insulation, used in more than 70% of projects. It offers a high R‑value per inch (approx. R‑5.7/inch) and is available with glass or foil facers. Polyiso boards can be tapered to create slope, aiding drainage. However, polyiso’s R‑value decreases slightly at extremely cold temperatures; using two layers can mitigate thermal bridging.

2. Extruded Polystyrene (XPS):

XPS has consistent R‑value (around R‑5/inch) and excellent moisture resistance. It is often used in inverted roof assemblies or as cover boards. XPS boards maintain thickness under load.

3. Expanded Polystyrene (EPS):

EPS is less expensive (R‑3.6–R‑4.5/inch) and available in various densities. It absorbs more moisture than XPS and requires protective membranes.

4. Mineral Wool:

Mineral wool boards offer fire resistance and sound attenuation. They have lower R‑value (R‑4–R‑4.2/inch) but remain stable at high temperatures. Mineral wool is often combined with polyiso to enhance fire resistance in commercial roof replacement.

5. Sprayed Polyurethane Foam (SPF):

SPF insulation is sprayed onto the roof deck, forming a monolithic surface with high R‑value (R‑6–R‑7/inch). It can create slope and seamless waterproofing. The UFGS notes that spray‑applied polyurethane foam roof insulation is specified separately. SPF requires experienced commercial roofing installers and regular coatings to protect from ultraviolet degradation.

🌡️ Table 4: R-Values of Common Commercial Roof Insulation Materials

| Insulation Type | R-Value per Inch | Moisture Resistance | Cost | Notes |

|---|---|---|---|---|

| Polyiso | R-5.6 to R-5.8 | Moderate | $$ | Most common; may lose R-value in extreme cold |

| Extruded Polystyrene (XPS) | R-5.0 | Excellent | $$$ | Consistent R-value; used in inverted systems |

| Expanded Polystyrene (EPS) | R-3.6–4.5 | Low–Moderate | $ | Cost-effective but absorbs water easily |

| Mineral Wool | R-4.0–4.2 | High | $$$ | Fire-resistant and sound-absorbing |

| Spray Polyurethane Foam (SPF) | R-6.0–7.0 | Moderate | $$$$ | High initial cost; seamless application |

Insulation and Roof Drainage

Insulation affects roof drainage because slope can be built into tapered insulation. The UFGS specifies that if providing a continuous slope in the deck is impracticable, tapered insulation should be used. Roofers often use polyiso boards cut to create slopes (e.g., ¼ in. per foot) or crickets to divert water around penetrations. Duke University’s standards emphasize that crickets must be used on all curbs and penetrations, with slopes twice that of the roof. Tapered insulation also helps form sumps around drains.

Cool Roofs and Energy Savings

Cool roofs combine reflective membranes and proper insulation to reduce cooling loads. The U.S. Department of Energy explains that conventional roofs can reach 150 °F on a sunny summer afternoon, but a reflective roof can stay more than 50 °F cooler. Cool roofs lower air‑conditioning requirements, improve indoor comfort and may extend roof service life. They also reduce urban heat island effects and can lower peak electricity demand. White TPO, PVC membranes or cool‑roof coatings on BUR or modified bitumen systems help achieve these benefits. For commercial roof replacement , combining a high‑R‑value insulation system with a cool roof membrane provides energy savings and may qualify for utility rebates.

Local Considerations for Knoxville, Tennessee

Climate and Weather Patterns

Knoxville lies in ASHRAE climate zone 4 (mixed‑humid). The region experiences hot summers, cold winters and significant rainfall. The 2014 National Climate Change Assessment notes that heavy rainfalls are increasing nationally and will continue to rise.

This makes proper drainage and secondary drainage critical in commercial roof replacement . Ensuring positive drainage within 48 hours, as defined by the IBC, helps prevent ponding and potential structural failures.

Energy Codes and Insulation Requirements

Under the 2012 IECC adopted in Tennessee, commercial roofs must have at least R‑25 continuous insulation above the deck in climate zone 4. PIMA recommends upgrading to R‑30. Additional insulation can reduce heating and cooling loads and may qualify for tax credits or rebates. Owners should verify local amendments with Knoxville’s building department. Litespeed Construction designs commercial roof replacement assemblies that meet or exceed code by layering polyiso insulation and providing tapered boards for drainage.

Rainfall Intensity and Drainage Design

Knoxville receives around 47 inches of rain annually. Intense storms can overwhelm drainage if not properly sized. The Roofing Contractor guidelines suggest using at least two drains for roof areas under 10,000 sq ft and adding a drain for each additional 10,000 sq ft. Duke University’s standards recommend spacing drains no more than 40 feet apart. Secondary (overflow) drains or scuppers should discharge water if primary drains are blocked. Litespeed Construction uses rainfall conversion data to size drainpipes and scuppers based on local rainfall intensity.

Local Expertise and Materials Availability

As a Knoxville‑based roofing contractor, Litespeed Construction understands the availability of membranes, insulation and accessories in the region. Local supply houses stock TPO, PVC, EPDM, BUR and modified bitumen systems along with polyiso and XPS insulation. Familiarity with regional suppliers helps ensure timely delivery and cost‑effective commercial roof replacement .

Sustainability and Rebates

Knoxville utilities may offer incentives for cool roofs or high‑R‑value insulation. The DOE lists potential rebates for installing reflective roofs and energy‑saving measures. Litespeed Construction assists clients in identifying and applying for incentives when planning commercial roof replacement projects.

🛠️ Table 5: Commercial Roof Replacement Decision Matrix

| Factor | Best Membrane Type | Best Insulation Type | Litespeed Recommendation |

|---|---|---|---|

| High Foot Traffic | PVC / BUR | Polyiso + Cover Board | GAF PVC or SBS-modified bitumen with HD cover board |

| Chemical Exposure (Grease, etc.) | PVC | Polyiso + Mineral Wool | GAF PVC KEE membrane system |

| Budget-Conscious | EPDM or TPO | EPS | EPDM with taped seams and layered EPS |

| Energy Efficiency Priority | TPO / PVC | Polyiso (R-30+) | White TPO with tapered polyiso for slope + R-value |

| Cold Climate + Freeze/Thaw | EPDM or SBS | XPS | EPDM with XPS insulation under a vapor barrier |

Working With Litespeed Construction

Litespeed Construction is a licensed and insured roofing company located in Knoxville, Tennessee. The company specialises in commercial roof replacement and repairs for a variety of building types, including offices, warehouses, retail centres and churches. Here’s why partnering with Litespeed Construction adds value to your commercial roof replacement specifications:

Litespeed’s engineers analyse your roof’s structural layout and design slopes, crickets, drain placement and secondary drainage to meet code and prevent ponding. They follow guidelines such as providing a minimum ¼ inch per foot slope and installing drains at appropriate intervals.

The team evaluates building use, foot traffic, chemical exposure and budget to recommend PVC, TPO, EPDM, BUR or modified bitumen membranes. They understand the long track record of PVC, the flexibility of TPO, the elasticity of EPDM and the redundancy of built‑up systems. Litespeed uses high‑quality membranes from reputable manufacturers.

Litespeed constructs roof assemblies that meet or exceed R‑30 requirements recommended by PIMA. They layer polyiso boards, design tapered insulation for drainage and install cover boards to protect membranes. The result is a roof that improves comfort and reduces energy costs.

The company’s crews are trained in heat‑welding, adhesive application and hot asphalt techniques. They adhere to safety protocols and manufacturer specifications, ensuring that commercial roof replacement projects carry full warranties.

Litespeed assists building owners in identifying rebates or tax incentives for cool roofs and high‑R‑value insulation. They also provide transparent proposals and help clients evaluate long‑term cost savings.

By trusting Litespeed Construction for your commercial roof replacement , you gain a partner that prioritises code compliance, energy efficiency and long‑term durability. Visit Litespeed Construction’s website to schedule a consultation or view project examples.

Commercial Roof Replacement Done Right

A successful commercial roof replacement demands a holistic understanding of drainage, membrane options and insulation. Drainage design must provide adequate slope, limit deck deflection, strategically locate drains and include secondary drainage. Membrane selection—whether PVC, TPO, EPDM, BUR or modified bitumen—should account for durability, chemical resistance, energy efficiency and budget. Insulation is equally critical: high R‑values reduce heat flow and meeting or exceeding R‑30 in Knoxville’s climate zone improves energy performance.

Litespeed Construction brings expertise in each of these areas. By following the specifications and best practices detailed here and engaging a qualified contractor, building owners in Knoxville can ensure their commercial roof replacement performs for decades, protects their investment and enhances energy efficiency. Don’t wait until your roof becomes a rooftop water park or your insulation starts acting like a sponge—reach out to Litespeed Construction today for a comprehensive assessment and a tailored commercial roof replacement solution. Call, click or send a carrier pigeon (okay, maybe stick with phone or email) to Litespeed Construction and let our team handle the heavy lifting while you focus on running your business.

Call us for a free estimate

Residential Roof Repair

If your home is in need of a roof repair, we are the #1 expert in Residential Roof Repair in the Knoxville area and you are at the right place! With over a decade of quality roof repairs, Litespeed will fix that leak fast and right the first time! Because we know how important your home is to you.

Emergency Roof Repair

As a homeowner, you never want to experience an Emergency Roof Repair, but there are times when Mother Nature has other plans in store. However, in the event of an emergency, it is important to have a go-to roofing contractor to contact to get professional repairs done quickly in order to prevent further damage.

Roof Leak Repair

Roof Leak Repair is something that we have been doing right for over a decade. We are fast and we get the job done correctly the first time.

If you need a repair, call us today and we can help you solve your problem fast.

Call: (865) 297-3286