In the world of commercial real estate, your roof isn’t just a structural necessity—it’s a capital investment. Failure to properly maintain and test your commercial roof can result in expensive damage, business disruption, and even legal liability due to safety hazards.

At Litespeed Construction, Knoxville’s top-rated commercial roofing contractor, we’ve seen firsthand how vital it is to verify commercial roof integrity using scientific, code-compliant testing methods. This article offers a deep dive into the various testing techniques that property owners and facility managers can use to ensure long-term protection and performance.

Key Takeaways

💡Commercial Roof Integrity is assessed through infrared thermography, moisture surveys, and core sampling.

💡Infrared scanning and nuclear moisture testing are two of the most effective non-destructive testing methods available.

💡The National Roofing Contractors Association (NRCA) and the U.S. Department of Energy recommend routine inspections at least twice annually.

💡Hiring certified professionals like Litespeed Construction ensures that your commercial roof is inspected using the latest technologies, improving lifespan and ROI.

What is Commercial Roof Integrity?

Commercial Roof Integrity refers to the overall structural soundness, waterproofing effectiveness, thermal resistance, and durability of a commercial roofing system. It encompasses:

- Load-bearing capacity

- Thermal insulation effectiveness

- Moisture intrusion resistance

- Membrane adhesion and sealing performance

- Compliance with building codes and fire safety standards

The U.S. Department of Energy highlights that poorly maintained roofs can lead to 30% energy loss in commercial buildings (source: energy.gov).

Commercial Roof Integrity Testing Methods

1. Visual Inspections: The First Line of Defense

A professional visual inspection is typically the starting point in evaluating a roof’s condition. Litespeed Construction’s trained technicians look for:

- Ponding water

- Blistering or alligatoring

- Flashing failures

- Membrane punctures

- Mold or algae growth

- Roof edge deterioration

These inspections are recommended twice a year (spring and fall), according to NRCA standards.

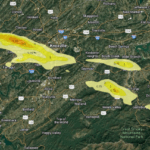

2. Infrared Thermography (IR Scanning)

Infrared thermography uses thermal imaging cameras to detect temperature variations across the roof’s surface, identifying:

- Wet insulation

- Trapped moisture

- Areas with poor thermal performance

🔍 Why It Matters

Water-saturated insulation emits heat differently than dry materials, making IR scanning ideal for non-invasive roof diagnostics.

📊 Stat Check

According to a study by the U.S. Army Corps of Engineers, IR scanning can detect up to 87% of subsurface moisture areas before visual signs appear.

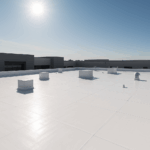

3. Electronic Leak Detection (ELD)

ELD systems use low-voltage or high-voltage electrical pulses to identify breaches in waterproofing membranes.

- Ideal for flat and low-slope commercial roofs

- Pinpoints leak locations with 99% accuracy

- Works on TPO, EPDM, PVC membranes

ELD is compliant with ASTM D7877 and D8231—standards issued by the American Society for Testing and Materials.

4. Nuclear Moisture Testing

A more advanced method, nuclear moisture testing involves a radioactive probe that emits neutrons into the roof system to detect hydrogen atoms (found in water).

- Non-destructive

- Extremely accurate

- Best for roofs with multiple insulation layers

According to ASTM D2924, this method is effective in detecting up to 99.5% moisture presence within roof insulation.

5. Roof Core Sampling

While invasive, core sampling is often used to verify the findings of thermal imaging or electronic tests.

- Physically removes a sample of the roof

- Provides direct insight into all roofing layers

- Confirms presence of moisture, insulation type, and thickness

Litespeed Construction uses core sampling selectively, ensuring minimal disruption to the structure while maximizing data accuracy.

6. Drone-Assisted Inspections

Drone technology is becoming increasingly popular for high-resolution aerial inspections.

- Safe and fast

- Provides thermal and optical imaging

- Reduces labor cost and time on large-scale roofs

Litespeed Construction employs FAA-licensed drone pilots to scan industrial and retail facility roofs across East Tennessee and beyond.

7. Wind Uplift Testing

FM Global Standard 1-52 outlines wind uplift resistance testing procedures. This test simulates high wind conditions to assess how well the membrane remains attached to the substrate.

- Required for certain commercial insurance policies

- Critical for facilities in hurricane or tornado zones (Knoxville included)

Wind uplift testing contributes directly to insurance compliance and building code certification.

Pros and Cons of Roof Integrity Testing Methods

| Method | Pros | Cons |

|---|---|---|

| Visual Inspection | Low cost, Fast | May miss subsurface issues |

| Infrared Scanning | Non-invasive, Accurate | Affected by weather |

| Electronic Leak Detection | Pinpoint accuracy | Higher cost |

| Nuclear Testing | Best for deep insulation | Expensive, requires licensing |

| Core Sampling | Direct data | Invasive |

| Drones | Safe, wide coverage | Cannot penetrate surface layers |

Web Ratings of Testing Methods

| Test Type | Industry Use Rating | Accessibility | Regulatory Backing |

|---|---|---|---|

| 🔍 Visual Inspection | ⭐⭐⭐⭐⭐ | ✅ High | 🏛️ NRCA |

| 🌡️ Infrared Scanning | ⭐⭐⭐⭐⭐ | ⚠️ Medium | 📘 ASTM |

| ⚡ ELD (Electronic Leak Detection) | ⭐⭐⭐⭐ | ❌ Low | 📘 ASTM |

| ☢️ Nuclear Moisture Testing | ⭐⭐⭐ | ❌ Low | 📘 ASTM |

| 🧪 Core Sampling | ⭐⭐⭐⭐ | ⚠️ Medium | 📘 ASTM |

| 🚁 Drone Scanning | ⭐⭐⭐⭐⭐ | ✅ High | 🛫 FAA, 🏛️ NRCA |

Why Choose Litespeed Construction for Roof Integrity Testing?

Located in the heart of Knoxville, TN, Litespeed Construction offers certified commercial roof inspection services backed by:

- Years of hands-on experience

- Cutting-edge infrared and drone technology

- Compliance with NRCA, ASTM, and DOE standards

- Local trust and national attention

We’re not just checking your roof; we’re protecting your investment, assets, and future.

FAQs About Commercial Roof Integrity

It refers to the health and durability of a commercial roof, including its resistance to weather, leaks, and structural degradation.

Twice a year—spring and fall—per NRCA recommendations.

Yes, it's non-destructive and widely used across industries, including military and aerospace.

Up to 99% when performed under ASTM standards.

Yes, with thermal and high-res cameras, drones offer powerful insight into surface anomalies.

When performed professionally, they are safe and minimally invasive.

Costs vary: visual ($300–$500), IR scan ($700+), nuclear/moisture ($1,000+).

Yes, especially wind uplift and leak detection testing are insurance-mandated.

20–40 years depending on material and maintenance. Testing increases lifespan.

Yes, we offer commercial services across East Tennessee and the surrounding region.