Rooftop HVAC units are a staple in commercial and some residential buildings, especially across hot and humid areas like Knoxville, TN. While these systems offer efficient climate control and save valuable interior space, they can also be a significant stressor on your roofing system — both structurally and functionally.

Understanding how rooftop HVAC units interact with your roofing material is critical to avoiding premature roof failure, drainage issues, and costly repairs.

This guide, backed by data from sources such as the U.S. Department of Energy and the National Roofing Contractors Association (NRCA), explores the complex relationship between HVAC units and the health of your roof.

Whether you’re a business owner managing a commercial property or a homeowner with a modern HVAC setup, Litespeed Construction breaks down what you need to know to protect your investment.

Key Takeaways

💡Improper installation or oversized units can stress your roof structure, leading to cracks, sagging, or collapse.

💡Penetrations, curbs, and drainage from HVAC systems often become leak entry points, especially without proper flashing.

💡Vibration, foot traffic, and thermal shock from HVAC cycles shorten roofing membrane life.

💡Professional roofing and HVAC coordination can prevent expensive repairs and extend roof lifespan.

1. Structural Impact: Load Stress and Design Limitations

Rooftop HVAC units can weigh hundreds to thousands of pounds depending on their tonnage and type. According to the U.S. Department of Energy, the average weight of a commercial rooftop HVAC unit ranges between 200 to 3,500 lbs depending on system size and cooling capacity.

Key Considerations:

| Unit Tonnage | Average Weight (lbs) | Roof Type Compatibility |

|---|---|---|

| 3-5 Tons | 200–500 | Most commercial flat roofs |

| 10-20 Tons | 800–2,000 | Steel-deck with reinforced joists |

| 30+ Tons | 2,500–3,500+ | Engineered for heavy HVAC loads |

Overloading a roof not designed for such weight leads to:

- Deck deflection or failure

- Cracking or sagging of roof membrane

- Increased vulnerability to ponding water

⚠️ Fact: As per the International Building Code (IBC), live roof loads including HVAC must not exceed 20 pounds per square foot (psf) without engineering review.

2. Moisture and Leak Risk from Rooftop HVAC Units

HVAC systems require penetrations through the roof deck for ducting, electrical, and condensate drainage lines. These are the #1 sources of water intrusion when not properly sealed or maintained.

Common Issues:

- Faulty flashing or deteriorated seals

- Condensation line backflow

- Ponding water near HVAC curbs

📊 According to the National Roofing Contractors Association (NRCA), up to 40% of commercial roof leaks originate around mechanical curbs and rooftop units.

Proper curb installation, drainage planning, and flash inspection should be part of every HVAC installation or service.

3. HVAC-Induced Wear and Tear on Roof Membranes

Rooftop HVAC units subject roofing materials to mechanical and environmental stress that can significantly reduce their lifespan.

Types of Stress:

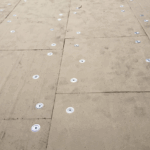

- Foot Traffic: Service technicians routinely walking on the roof compress insulation and damage membranes.

- Vibration: Ongoing HVAC vibrations lead to membrane separation and cracks.

- Thermal Shock: Cyclical heating/cooling causes expansion/contraction of the roofing system, weakening seams.

Lifespan Impact by Roofing Material Type:

| Roof Type | Avg. Lifespan (No HVAC) | With HVAC (Poor Maintenance) |

|---|---|---|

| EPDM (Rubber) | 25–30 years | 15–20 years |

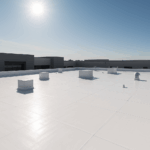

| TPO | 20–25 years | 12–18 years |

| Built-Up Roofing | 30–35 years | 18–25 years |

4. Energy Efficiency and Ventilation Challenges

Ironically, the HVAC unit designed to optimize comfort may sabotage building energy efficiency when not well-integrated with the roofing system.

Potential Problems:

- Improper sealing around curbs causes conditioned air loss.

- Condensate overflow increases roof humidity and degradation.

- Heat discharge from HVAC units creates urban heat island effects on white TPO or reflective roofs.

5. Importance of Routine Maintenance and Professional Installation

Poorly coordinated work between HVAC installers and roofers can result in irreversible roof damage. That’s why Litespeed Construction emphasizes:

- Joint inspections between HVAC and roofing teams

- Post-installation infrared moisture scanning

- Bi-annual roof inspections focusing on rooftop units

Pros and Cons of Rooftop HVAC Units

| Pros | Cons |

|---|---|

| Saves interior space | Adds structural load to the roof |

| Easier service access | Risk of leaks at penetration points |

| Aesthetically minimal impact | Increases foot traffic and vibration |

| Reduces interior noise levels | Decreases roof lifespan if not properly managed |

| Good for commercial zoning layouts | Higher installation and maintenance costs |

FAQs about Rooftop HVAC Units

They range from 200 to over 3,500 lbs depending on system size and purpose.

Yes — especially if the curbs, flashing, or drainage systems are improperly installed or maintained.

Flat commercial roofs made from EPDM, TPO, or built-up roofing with reinforced decking.

At least twice a year, and after every HVAC installation or service.

Yes — typically by 20–40% without proper maintenance and protective walk pads.

Yes, split systems or ground-mounted units are alternatives, especially for homes.

Signs include sagging, cracking, ponding water, or soft spots on the roof deck.

Absolutely. Coordination ensures leak prevention and long-term roof health.

Humidity and heat increase strain on both the HVAC system and the roofing membrane.

Litespeed Construction in Knoxville offers specialized inspections for HVAC roof wear.

Need a Rooftop Roof Inspection in Knoxville?

Litespeed Construction is Knoxville’s trusted roofing expert, with years of experience handling commercial roofs affected by HVAC systems. From full inspections and emergency leak repairs to preventive maintenance plans, our licensed team ensures your roof and HVAC work together — not against each other.