When it comes to working at heights, safety isn’t optional—it’s the law. Falls from commercial rooftops remain one of the leading causes of fatalities in the construction industry. In fact, according to the Occupational Safety and Health Administration (OSHA), falls account for more than 33% of all construction deaths each year.

For commercial property owners and facility managers, especially in cities like Knoxville, TN, understanding how to implement fall protection on commercial roofs is not only a regulatory requirement but a critical component of workplace safety. Whether you manage a retail complex, industrial facility, or office building, ensuring fall protection systems are properly installed can save lives—and protect your business from liability.

Key Takeaways

💡OSHA requires fall protection at heights of 6 feet or more on commercial roofs

💡Effective systems include guardrails, safety nets, personal fall arrest systems (PFAS), and warning line systems.

💡Site-specific fall protection plans are legally required for employers and must be documented and enforced.

💡Hiring Professionals Can Improve Insurance Outcomes

Why Fall Protection on Commercial Roofs Matters

Falls from elevation remain the leading cause of workplace fatalities in construction, according to the U.S. Bureau of Labor Statistics (BLS). In 2023 alone:

| Category | Data (2023) |

|---|---|

| Fatal falls in construction | 388 deaths |

| % of total construction deaths | 34% |

| Fall deaths from roofs | 160+ |

| OSHA citation for fall violations | #1 most frequently cited violation |

Commercial roofs often include obstacles, unstable surfaces, and sloped designs that amplify the risks. OSHA and state agencies, including Tennessee OSHA (TOSHA), require employers to have proactive safety measures in place to prevent these accidents.

What OSHA Requires for Fall Protection on Commercial Roofs

The Occupational Safety and Health Administration (OSHA) mandates fall protection under standard 29 CFR 1926.501, which requires employers to provide protection when workers are exposed to fall hazards of 6 feet or more.

OSHA’s Approved Fall Protection Methods:

| System | Description |

|---|---|

| Guardrail Systems | Perimeter railings to prevent falls at edges |

| Safety Net Systems | Nets installed below the work surface to catch falling workers |

| Personal Fall Arrest Systems | Harnesses with anchors and lifelines to stop a fall in progress |

| Warning Line Systems | Marked lines that warn of proximity to an unprotected roof edge |

| Roof Hatch Guards | Guards around openings or hatches on the roof |

| Designated Areas | Specific zones with limited access and control measures |

Employers are also responsible for employee training, equipment inspection, and maintaining written fall protection plans.

Step-by-Step Guide: How to Implement Fall Protection on Commercial Roofs

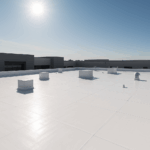

Implementing an effective fall protection system involves more than installing equipment. It requires a strategic plan aligned with OSHA and TOSHA regulations.

Step 1: Conduct a Fall Hazard Assessment

Begin with a site-specific hazard analysis. This should identify:

- Unprotected roof edges

- Skylights or roof hatches

- Trip hazards like cables, tools, and materials

- Sloped or unstable roof surfaces

- Weather-related risks (ice, rain, wind)

Litespeed Construction offers free roof safety inspections in Knoxville, TN to help identify these hazards.

Step 2: Choose the Right Type of Fall Protection System

Common Systems Installed by Litespeed Construction:

| System Type | Best Use Case | Pros | Cons |

|---|---|---|---|

| Guardrails | Flat roofs, frequent maintenance zones | Passive protection, easy install | Visual impact, not ideal for slopes |

| Safety Net Systems | Large open work areas | Full coverage | Costly, installation complexity |

| PFAS (Harness Systems) | High-mobility tasks on sloped or large roofs | High versatility | Requires training, user compliance |

| Warning Lines | Low-risk maintenance zones | Easy setup, cost-effective | Only legal in combination with monitors |

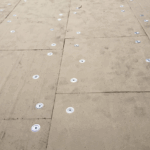

Step 3: Install Roof Anchors and Lifeline Systems

Roof anchors are critical for PFAS. They must meet OSHA 5,000 lb load requirements per 1926.502(d)(15).

Types of anchors include:

- Permanent Anchors – For long-term access and recurring roof maintenance

- Temporary Anchors – For short-term projects

Litespeed Construction uses certified anchor installation systems tested for commercial building materials.

Step 4: Train Your Employees

OSHA mandates that all workers exposed to fall hazards receive training under 29 CFR 1926.503. Training should include:

- Equipment use and inspection

- Emergency rescue procedures

- Recognizing hazards and reporting unsafe conditions

Step 5: Create a Written Fall Protection Plan

If your commercial building does not use conventional fall protection (e.g., due to slope or design), a site-specific plan is required by OSHA.

Key contents of a plan:

- Identified hazards

- Selected protection systems

- Equipment inspection logs

- Names of trained employees

- Rescue and emergency protocols

Litespeed Construction helps clients build OSHA-compliant fall protection plans tailored to their facility.

FAQs: Fall Protection On Commercial Roofs

Anytime workers are exposed to a drop of 6 feet or more, per OSHA guidelines.

Guardrails and PFAS are the most commonly used for flat roofs.

Before each use, and formally every 6 months by a qualified person.

No, they must be used with a safety monitor system to be OSHA compliant.

Yes, under standard 1926.503, training is required for all employees exposed to fall hazards.

Yes, temporary systems are effective for short-term work but must still meet OSHA standards.

Absolutely. Litespeed Construction offers custom fall safety designs for unique roofs.

Yes, systems like roof anchors and guardrails can be added to existing buildings.

Costs vary but generally range from $3,000–$20,000+ depending on the roof size and system type.

We're OSHA-compliant, locally trusted in Knoxville, and specialize in roofing-specific safety systems.